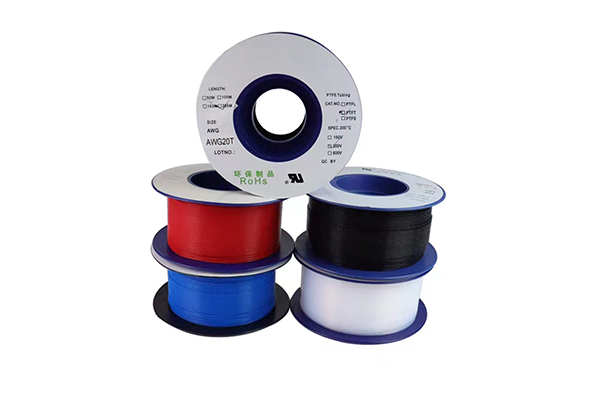

Polytetrafluoroethylene extrusion tube is made by mixing polytetrafluoroethylene high-pressure dispersing resin with additives into a paste, extruding it from a compact, and then debinding and sintering it. It can be made opaque and semi transparent according to different needs. Due to its advantages of corrosion resistance, aging resistance, non stick, self-lubricating, and good insulation properties, polytetrafluoroethylene can be used for a long time from -180 ℃ to+260 ℃, and is widely used in chemical, mechanical, electronic, pharmaceutical, aviation and other fields.

- Home

- About Us

- Products

-

Moulded board

-

Turning plate/turning flattening plate

-

Black board

-

Staircase board

-

Anti static board

-

Color board

-

bar

-

Black rod

-

Anti static rod

-

iberglass rod

-

Insulation pipe

-

FEP transparent tube/PFA tube

-

Molded bar material

-

Teflon wire

-

Teflon Film

-

PTFE gasket, washer

-

Teflon high-temperature tape

-

PTFE machined parts

-

- Production Equipment

- Application

- News

- Contact Us